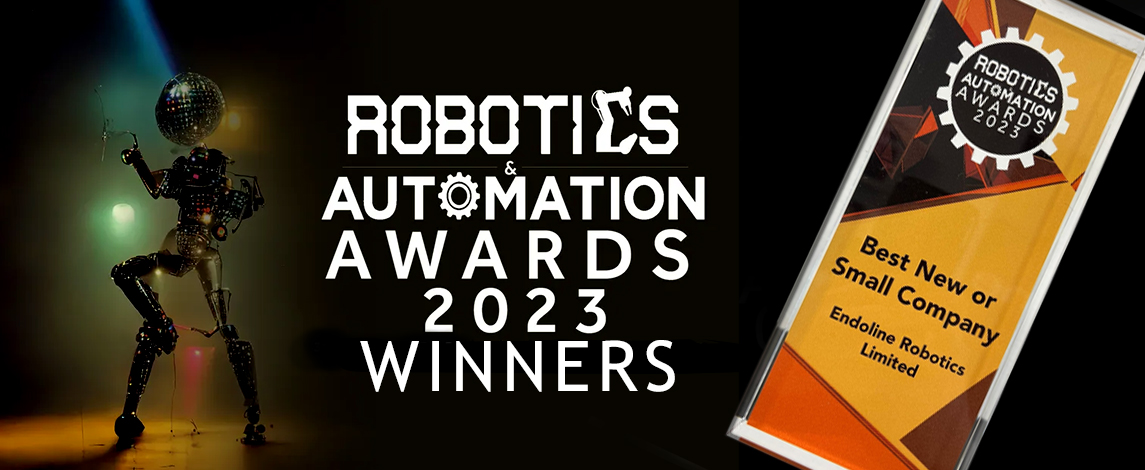

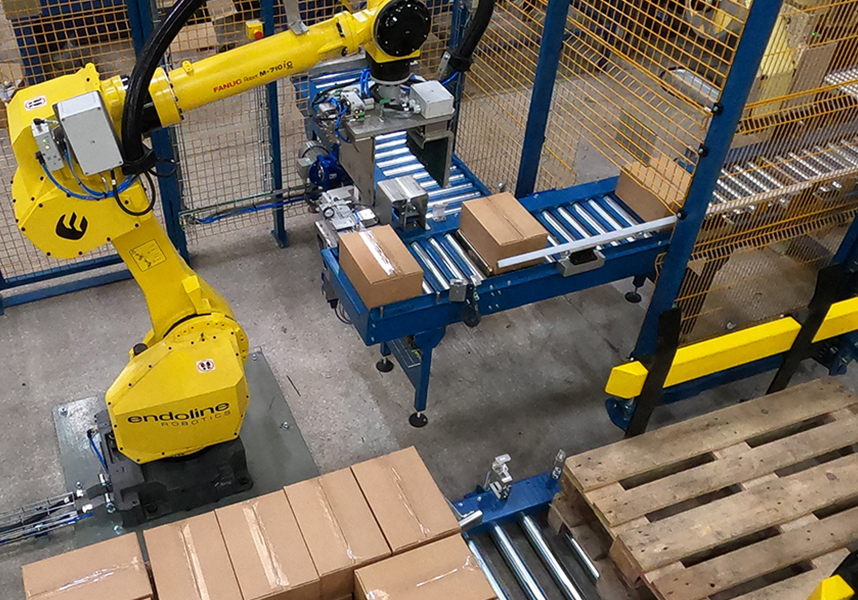

Automated Robotic Palletiser Solutions

Our automated palletisers utilise modern robotics & technologies capable of covering multiple production lines & different packaging types. Our systems are built to provide high pallet loading accuracy, reduced operational costs and increased productivity with minimal maintenance requirements and downtime, offering good return on investment and low cost of ownership.

Automated case packing solutions

Our automated case packing systems are designed and built to handle many different types of packaging at high speeds. Casepackers can substantially reduce operational costs and provide a very fast return on investment. Our compact modular designs can easily integrate into existing packaging lines and compact spaces. The modular design of our systems also allows for staged installations and progressive upgrades over time.