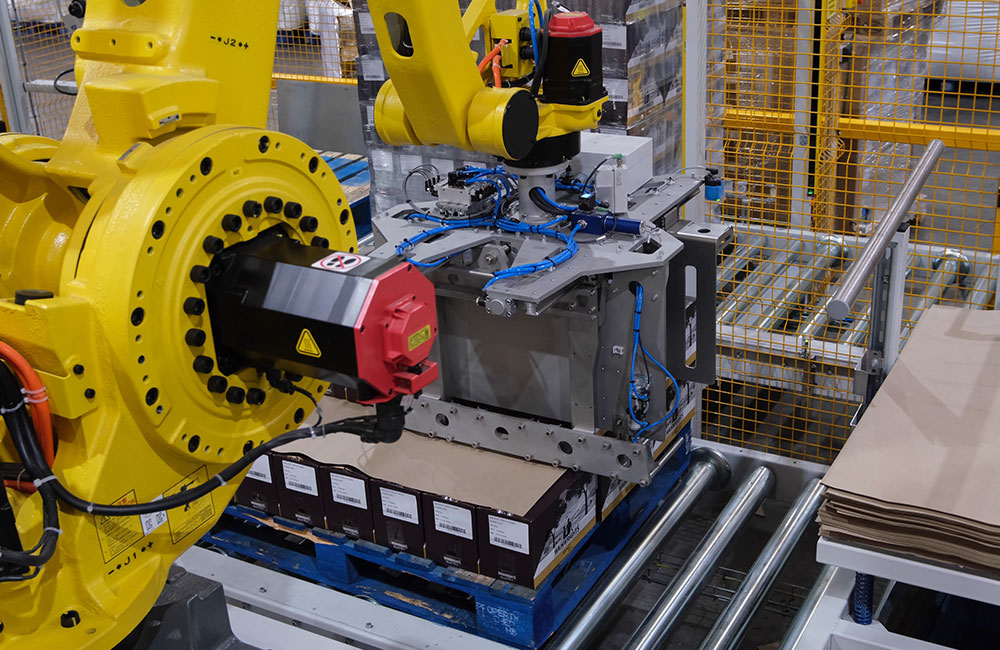

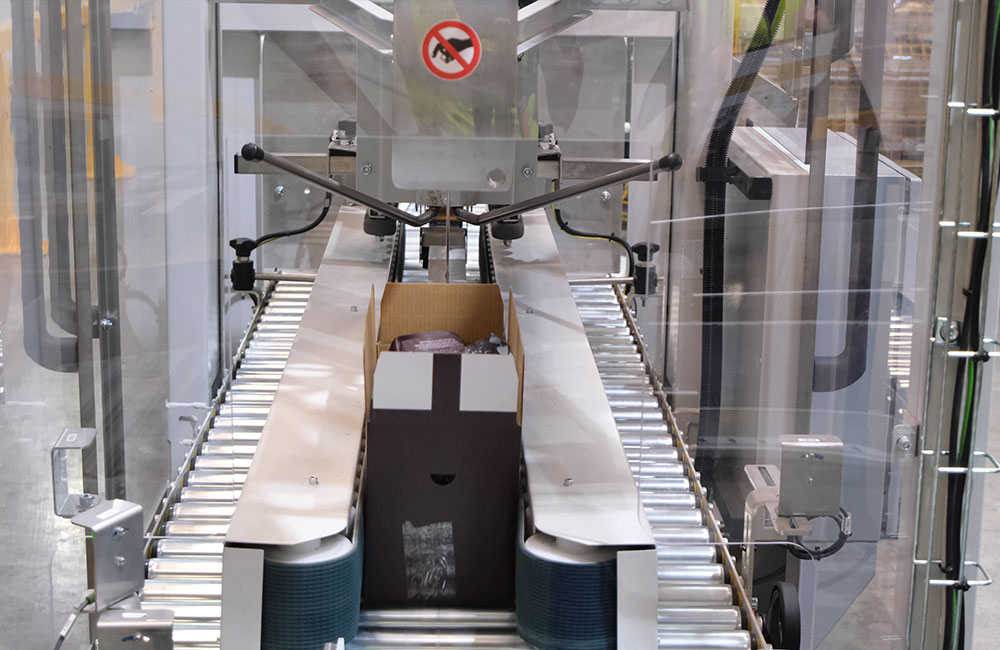

BREAKFAST CEREALS

LIFE HEALTH FOODS – BESPOKE PALLETISING SYSTEM

Endoline Robotics transforms productivity for top supermarket cereal supplier.

It is the largest and most innovative installation in Endoline Automation’s 42-year history. Valued at over £2.5 million, it is also the biggest order since Endoline Robotics launched at PPMA 2019. For Life Health Foods located in Peterborough, doubling production output has delivered transformational business benefits.