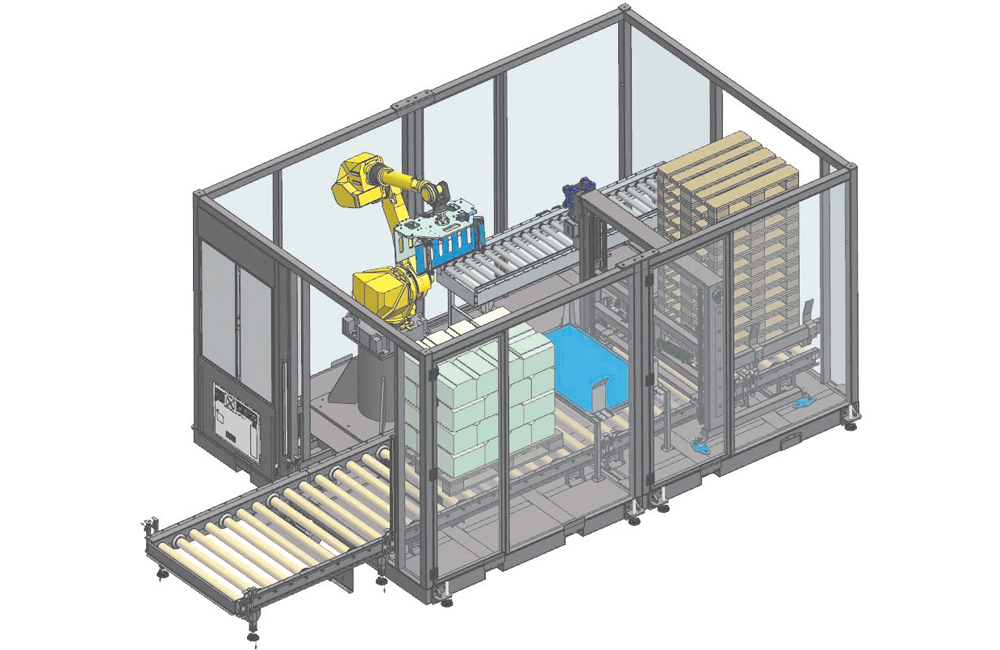

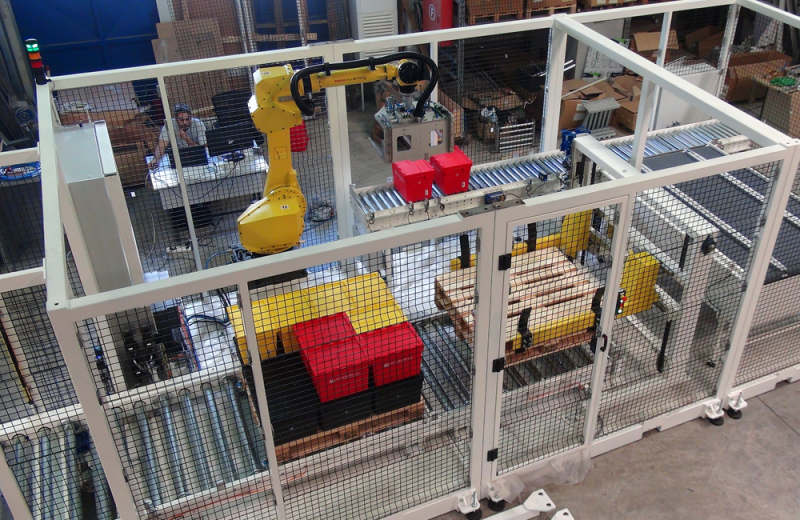

1000 SERIES

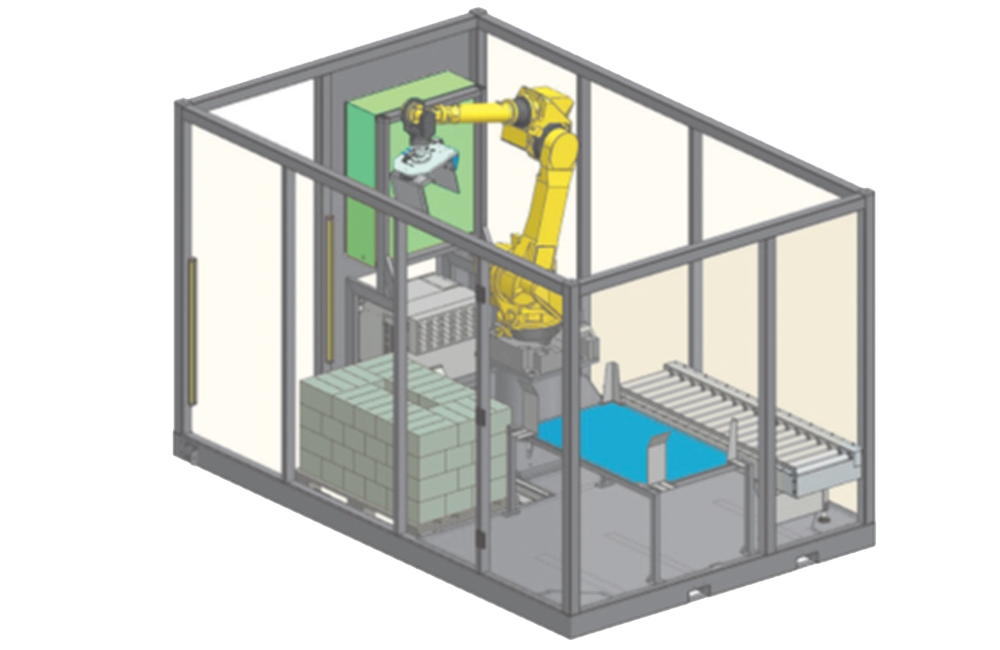

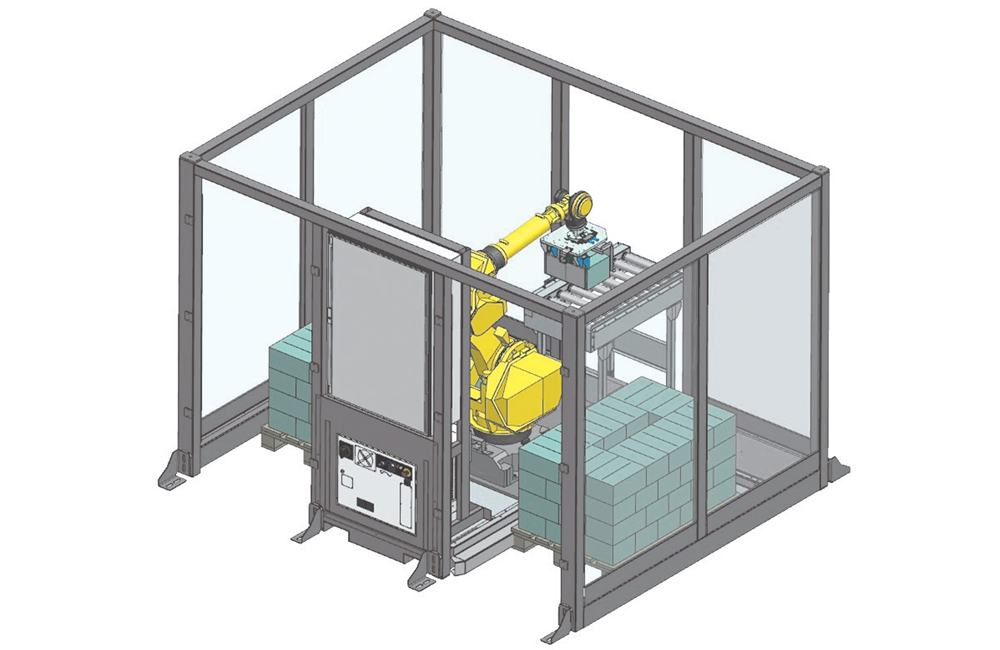

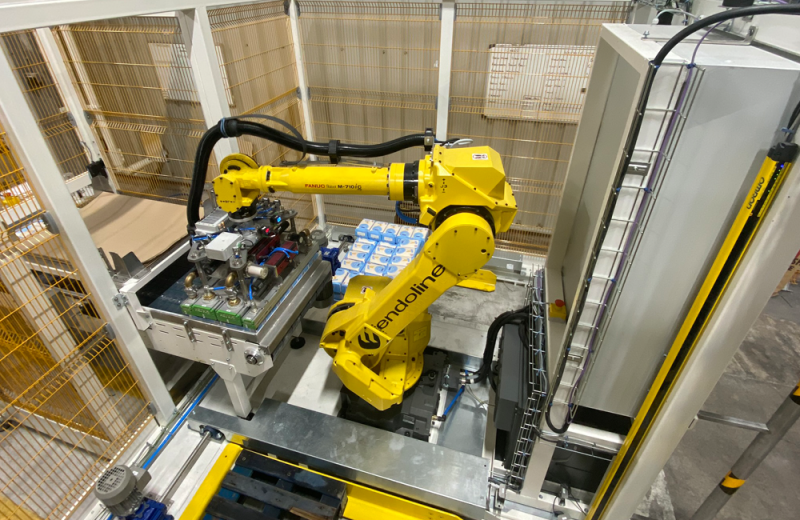

The Endoline Robotics 1000 series is a Plug & Play Robotic Palletiser that receives products directly from the production line and palletises them accordingly to pre-defined patterns. Using a FANUC robotic arm, it ensures high speed and precise product handling while its compact design makes it ideal for sites with limited space.

The ‘Plug & Play’ features of the 1000 series makes integration to the line extremely easy. Non-specialised personnel can install, commission and even move the system to different lines within the factory. Its compact design means the system can be moved by forklift.

The 1000 series is IoT ready and incorporates the latest technologies of industry 4.0.

To see how our Robotic Palletising Systems can be adapted to different products types go to palletising solutions.